As manufacturing technologies evolve at a rapid pace, optical laser systems are revolutionizing 3D production. Thanks to advanced optical laser systems, greater precision, speed, and quality are becoming standard in production processes. But why are these technologies so crucial, and what benefits do they offer manufacturers? Let's explore the details.

Basics of Optical Laser Technology

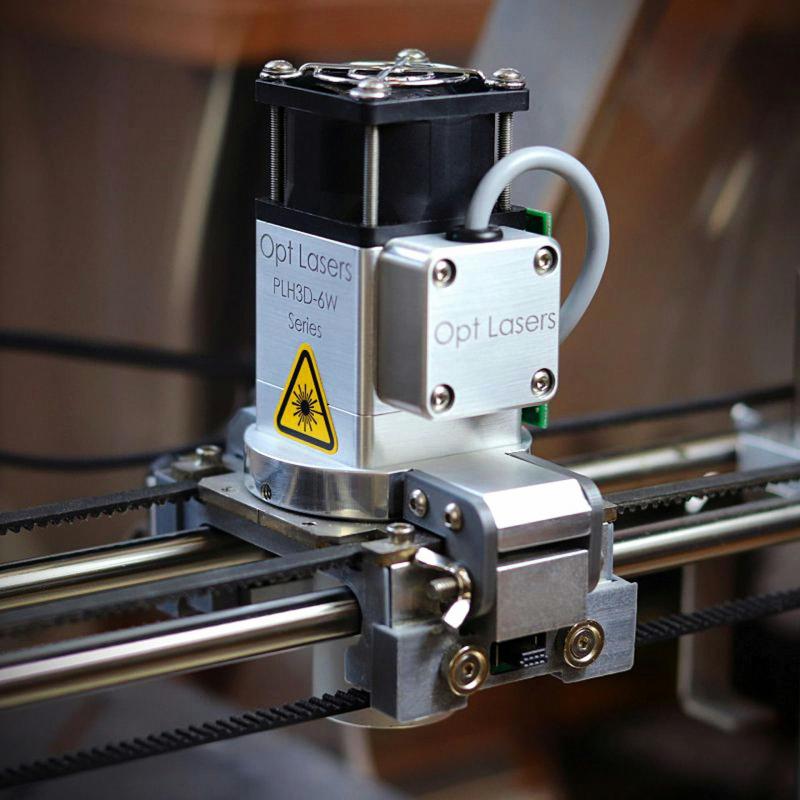

Optical laser technology enables light to be focused at high intensity, allowing micrometer-level operations on materials. Laser beams can be integrated into production with different wavelengths and power levels for cutting, welding, marking, and surface treatment applications.

Applications of Optical Lasers in 3D Manufacturing

- Precision cutting of metal and plastic surfaces

- Surface enhancement in additive manufacturing systems

- High-resolution micromechanical production

- Laser sintering and welding processes

Advantages of Optical Laser Systems

Compared to traditional manufacturing methods, optical laser systems offer the following advantages:

| Advantage | Description |

|---|---|

| High Precision | Micron-level operation capabilities minimize error rates. |

| Less Material Waste | Processes are applied only where needed, increasing efficiency. |

| Automation Integration | Easily integrates with robotic systems. |

| Low Maintenance Cost | Fewer mechanical parts result in lower failure risk. |

Step Into the Future of Production with 3D Photonics

At 3D Photonics, we redefine the boundaries of 3D manufacturing with innovative optical laser systems. Our precision-based solutions are used across a wide range of industries from industrial production to defense. If you are aiming for efficient outcomes in both time and cost, you're in the right place.

Frequently Asked Questions

Which materials are compatible with optical laser systems?

They can be used with metals, plastics, ceramics, and composite materials with high precision.

What are the benefits of optical lasers in 3D manufacturing?

They provide precision production, fast prototyping, low error rates, and high surface quality.

Which sectors do 3D Photonics solutions serve?

We offer solutions in automotive, defense, medical devices, electronics, and many more industries.

Conclusion: Precision is Now in Your Hands

Optical laser technology is becoming the key to next-generation 3D production. With benefits such as high accuracy, faster production, and reduced costs, investing in this technology means investing in the future. Contact us today and elevate your production.

- Is Micron-Level Processing Possible with Lasers? How It's Achieved

- Recent Developments in Fiber Laser Technology

- 5 Key Factors That Define Quality in Optical Systems

- What Is Laser Marking? Permanent and Reliable Traceability Solutions

- Using Spectrometers in Industrial Applications

- Laser Cutting vs CNC: A Comparative Guide

- Optical Solutions in 3D Manufacturing: The Power of Precision

- The Role of Laser in the Defense Industry: Next-Generation Security Technologies

- What Are Optical Filters Used For? The Impact of Right Selection on Production

- FABTECH Chicago, September 8-11, 2025

- 3D Photonics at FABTECH 2024: Showcasing Advanced Laser Technologies for Industrial Applications

- 3D Photonics Showcases Innovative Laser Solutions at EUROBLECH 2024

- What is Photonics?

- Robot Investments Summit | 20-23 December | Istanbul

- 16. Blechexpo | 7 - 10 November | Messe Stuttgart