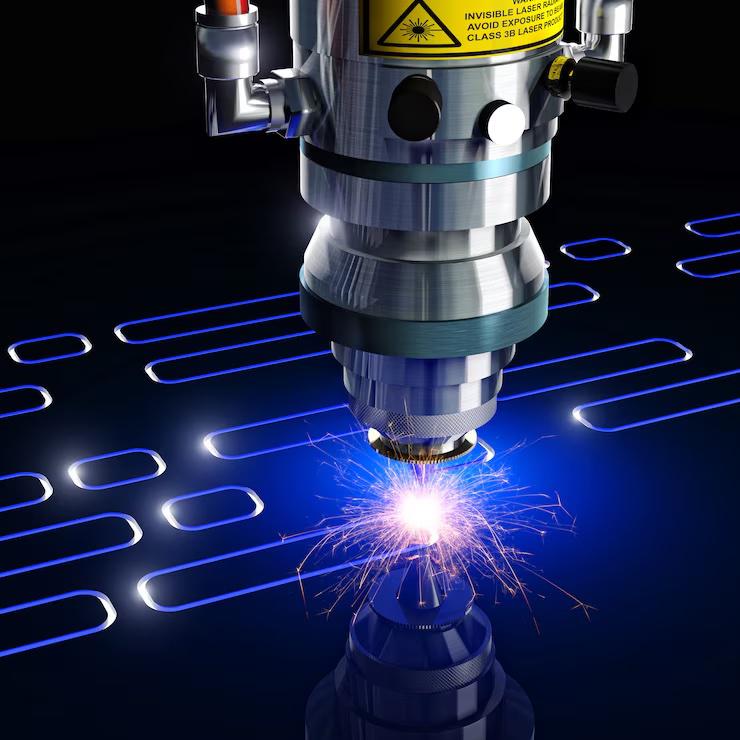

As technology advances, micron-level precision has become a necessity in modern manufacturing. But is it really possible to achieve such tiny-scale processing with lasers? Let's explore how fiber laser technologies make micron-level machining a reality.

High Precision with Fiber Laser Systems

Within laser systems, fiber lasers excel with their wavelength stability, focusing ability, and power density. Sub-micron cutting, marking, and drilling are now routinely achieved with advanced fiber laser systems.

Key Factors Enabling Micron-Level Processing

- Short Wavelength: Fiber lasers produce a smaller beam diameter, enabling more precise focus.

- Advanced Optical Components: High-quality lenses and mirrors concentrate the laser energy into the tiniest possible spot.

- Fast and Accurate Control Systems: Servo motors and precision software allow micron-level positioning and movement.

Application Areas

Micron-level laser processing is crucial in medical device manufacturing, microelectronics, precision mechanical parts production, and biotechnology sectors.

Micron-level processing with fiber laser systems is not only possible but increasingly common in industrial applications. With the right system and parameters, even the smallest details can be machined with stunning precision.

Frequently Asked Questions

How small can laser processing achieve?

Advanced fiber laser systems can achieve cutting and marking with precision down to a few microns (μm).

Do you need special optics for micron-level processing?

Yes, high-quality optical components and a stable laser source are essential for accurate micron-scale machining.

- Is Micron-Level Processing Possible with Lasers? How It's Achieved

- Recent Developments in Fiber Laser Technology

- 5 Key Factors That Define Quality in Optical Systems

- What Is Laser Marking? Permanent and Reliable Traceability Solutions

- Using Spectrometers in Industrial Applications

- Laser Cutting vs CNC: A Comparative Guide

- Optical Solutions in 3D Manufacturing: The Power of Precision

- The Role of Laser in the Defense Industry: Next-Generation Security Technologies

- What Are Optical Filters Used For? The Impact of Right Selection on Production

- FABTECH Chicago, September 8-11, 2025

- 3D Photonics at FABTECH 2024: Showcasing Advanced Laser Technologies for Industrial Applications

- 3D Photonics Showcases Innovative Laser Solutions at EUROBLECH 2024

- What is Photonics?

- Robot Investments Summit | 20-23 December | Istanbul

- 16. Blechexpo | 7 - 10 November | Messe Stuttgart