Industrial Applications with ABL Technology

Battery Welding

In Li-ion battery production, laser welding is used in delicate processes such as joining electrode layers and cell assembly. Laser welding improves the structural integrity and performance of the battery by offering a high level of control and automation. This technology increases the speed and efficiency of production processes while maximizing battery safety.

Defense Industry

Adjustable Beam Lasers have been developed for use in defense industry applications. One example is their use in surface hardening and precise hole drilling processes in the defense industry.

3D Printing

Adjustable Beam Lasers can be used to create complex 3D models and prototypes through a process called laser sintering, where the laser melts and fuses fine powder particles to form a solid object.

Automotive

Adjustable Beam Lasers offer convenience and speed in deep penetration and welding of different metals in the automotive industry.

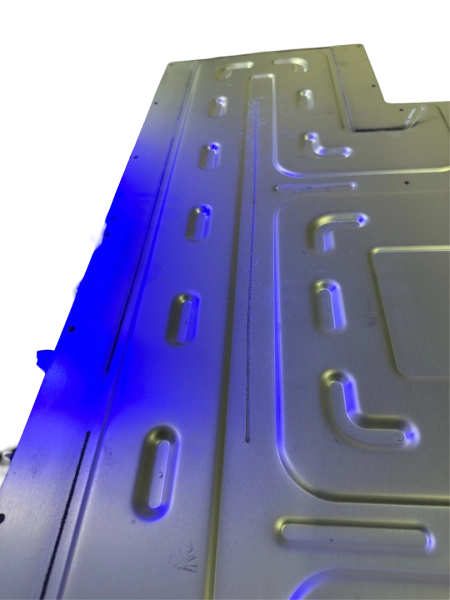

Battery Cooling Systems

Adjustable Beam Lasers used in welding applications reduce the risk of errors and increase efficiency by providing high precision and fast welding processes. They also minimize the formation of weld spatter and can tolerate larger gaps compared to traditional laser welding.

Usage fields of ABL Lasers

Battery Production

3D Photonics ABL can be used to cut and weld various components that make up an EV battery, such as lithium-ion cells and battery pack casings. The laser beam allows for precise and efficient cutting and welding by focusing on a small spot with high energy density. This can help improve the performance and lifespan of the battery by enabling precise and efficient production.

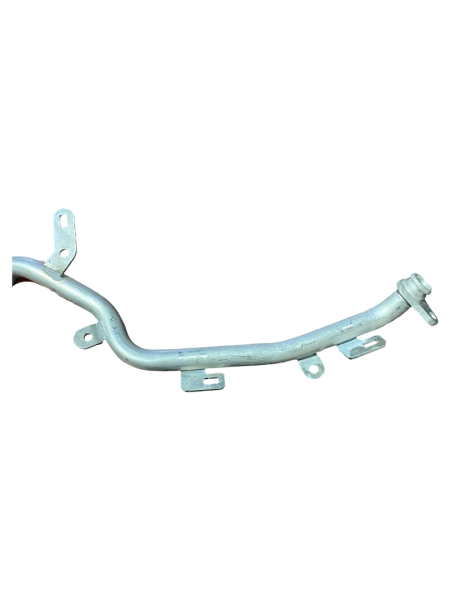

Engine and Transmission Components

3D Photonics ABL can be used to cut and weld the metal components of EV engines and transmissions. The high precision and efficiency of laser cutting and welding can help improve the performance and durability of these components.

Body Manufacturing

3D Photonics ABL can be used for welding the body of an EV. This process, known as laser welding, can enhance the overall quality of the body and also reduce costs. Laser welding is highly precise and efficient process that allows for the welding of complex geometries and tight tolerances.

Maintenance and Repair

3D Photonics ABL can be used for maintenance and repair of EV components such as the battery and power electronics, as well as the body of the EV. The high precision and efficiency of laser cutting and welding can help improve the lifespan and performance of the EV through precise and efficient repair work.

Industry 4.0

3D Photonics ABL can be quickly integrated into factories’ MES systems through industrial integration 4.0. They can be easily added to industry 4.0 data collection systems and provide access to data through OPC-UA. They can also be seamlessly integrated with ABB, FANUC, and KUKA robots.

In the dynamic realm of the automotive industry, Adjustable Beam Lasers (ABL) emerge as a transformative force, offe-

ring a host of advantages that redefine the way welding processes enhance quality, efficiency, and cost-effectiveness.

Enhanced Welding Quality

ABL lasers ensure high-quality, precise welds, reducing the risk of structural weak-nesses in automotive components.

Faster Production

The ability to weld at high speeds accelerates the manufacturing process, leading to increased productivity.

Reduced Rework

Virtually spatter-free welding minimizes the need for rework, saving time and resources.

Cost Savings

Improved efficiency and reduced rework translate into cost savings in automotive production.